Back Customised solar logistics solution for custom-built solar panels

Success Stories

A solar manufacturer mastered their logistics to power a Dubai pavilion

Customer:

Solar glass manufacturer in architectural design

Industry:

Renewables, solar energy

Solution:

End-to-end solution for custom-sized solar panels

- Precision delivery

- Continued partnership

- Reliable safeguards

The goal was seemingly straightforward.

Safely deliver 100 containers with over 28,000 custom-made solar panels to Dubai.

In the southern part of the city, an architectural masterpiece was underway: a pavilion, plus a group of dynamic energy trees designed to follow the sun’s path.

The goal of the winding complex would be both experiential and functional—offering an oases-like experience for events while generating its own energy despite the arid climate.

And the first detail you see? Custom-made, solar glass panels.

These panels are the work of a European-based manufacturer specialised in building integrated photovoltaics. A company consisting of engineers, technicians, and experts in constructive glass- and metal construction. Their work is defined around implementing individual customer ideas. Without a stretch of the imagination, this means their logistics provider would need to work in the same way.

After being referred by another one of our customers, the solar panel manufacturer reached out to us for the pavilion project.

The craft of an end-to-end logistics plan for custom-made solar panels

The project required logistics expertise that went beyond standard carrier bookings and trucking transport. It started with a general evaluation at the manufacturer’s facility in Europe which concluded: everything was needed—from forklifts and ramps to load the trucks to certified packaging and professional stuffing.

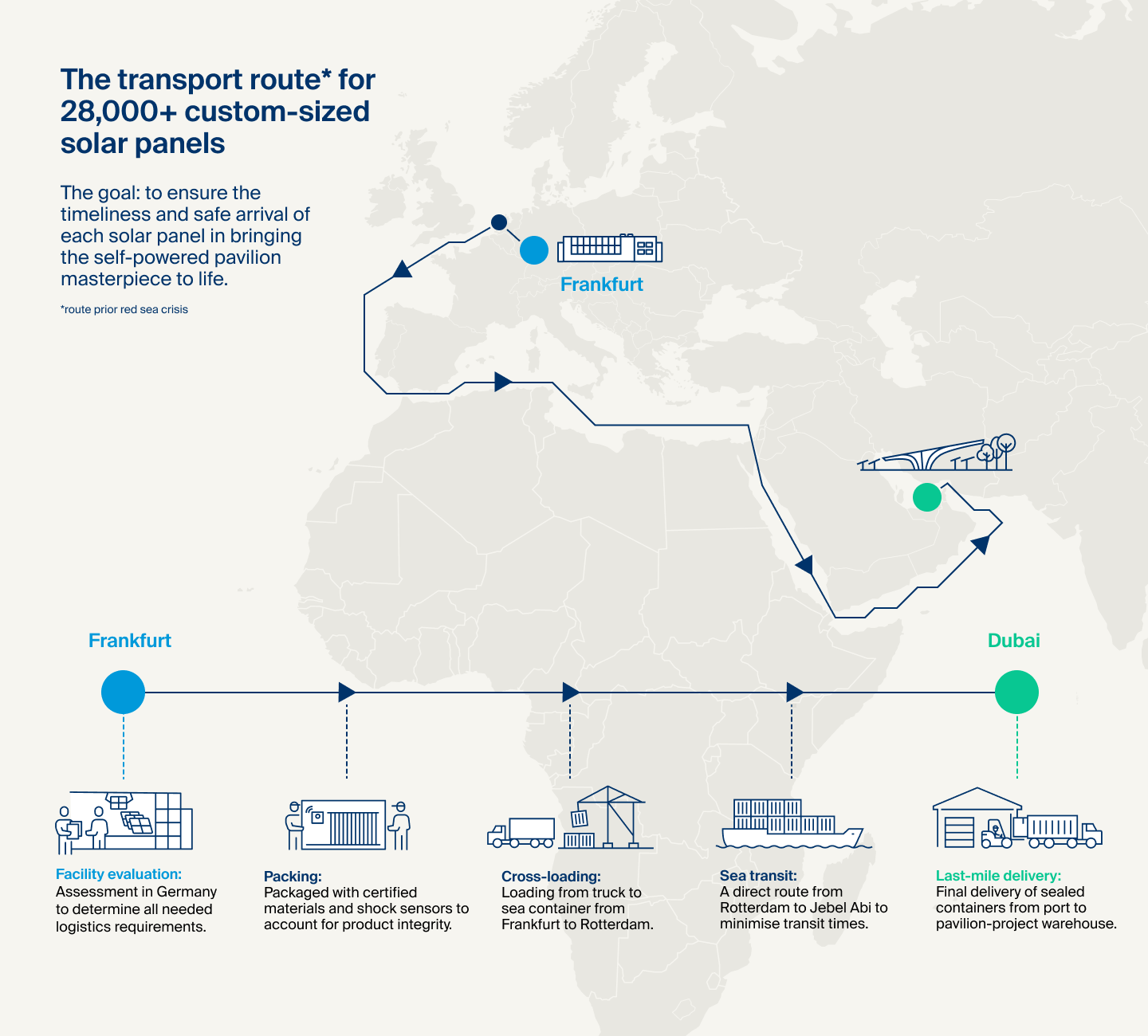

Beyond the facility came transportation considerations. What routes are the most efficient? Timeliness, availability, number of handlings, and a price that fits the value were all on the table.

Where do we have the most control to avoid the panel’s susceptibility to damage? We looked at our network’s capabilities. We would apply shock sensors at a container freight station in Frankfurt to ensure professional handling and insurance coverage for each of the 26 crates before cross-loading from the truck to sea container in Rotterdam.

From there, 100 sea containers carrying 286 solar panels each, then made the longest leg of the journey from Rotterdam to Jebel Ali.

The longest leg, but also the most direct when considering sea transportation between Europe and the United Arab Emirates*. As the solar panels arrived in Jebel Ali, they were kept in their sea container and loaded directly onto a chassis and trucked to the pavilion project’s warehouse.

And as simple as that last leg might seem, it was the final layer of security to reduce handlings by keeping the solar panels in the certified packaging until the final consignee could receive them with a seal number on the bill of lading.

*as long as the red sea crisis continues to impact sea transportation, the most direct route between Rotterdam and Jebel Ali is currently around the Cape of Good Hope.

Key considerations for PV solar transportation

- Shock sensors: the integrity of the solar panels arriving as promised was important for the success of the pavilion project. For each specialty-designed wooden crate, 11 custom-sized solar panels were securely packed and fitted with shock sensors to account for product integrity upon arrival.

- Route options: the ideal route considered timeliness, security and the needed capabilities of our logistics network, moving the panels from Frankfurt to Rotterdam and from Jebel Ali to the pavilion site.

- Packaging: certified materials for packing and securing the panels during road and sea transportation was an extra precaution taken to avoid possible damage. Only one container showed a triggered shock sensor and was compensated with Nacora insurance.

Results

Walking up to the entrance of the site in Dubai, you can feel the temperature drop as much as 10 degrees under the presence of the 130 metre-tall, oval-shaped pavilion generating its own energy. The solar panels, now fitted atop the canopy and the eighteen energy trees surrounding it, are expected to generate four gigawatt hours of electricity annually. That is like fueling a car to drive halfway to Mars (112.5 million kilometers) or making the drive from Lisbon to Seoul over 7,500 times.

The pavilion is an incredible accomplishment for self-sustaining innovation in architectural design. We are proud to have contributed to the timely delivery of each of the 28,000+ solar panels needed for the project and to have earned the confidence of our customer to do it well and do it right.

We are proud logistics partners of solar companies throughout the world. The expertise needed to manage solar logistics projects from manufacturing, planning and distribution is key in building up supply chains that are resilient and perform for the benefit of your customers.