Back Specialised semiconductor sub-fab logistics

Services

Your partner for reliable semiconductor sub-fab logistics

Sub-fabs are critical to supporting cleanroom operations. Unplanned stoppages or delays in a sub-fab can seriously undermine the production of semiconductor wafers, which can result in severe financial losses.

Semiconductor sub-fab logistics are complex and must be precisely planned and coordinated. Kuehne+Nagel understands every facet of semiconductor facility logistics.

We excel in providing sub-fab and cleanroom logistics solutions. Our processes ensure safe and prompt sub-fab equipment transportation and sub-fab material handling.

Kuehne+Nagel can provide you with tailored semiconductor manufacturing logistics solutions that guarantee the safety, stability, and predictability of your sub-fab operations.

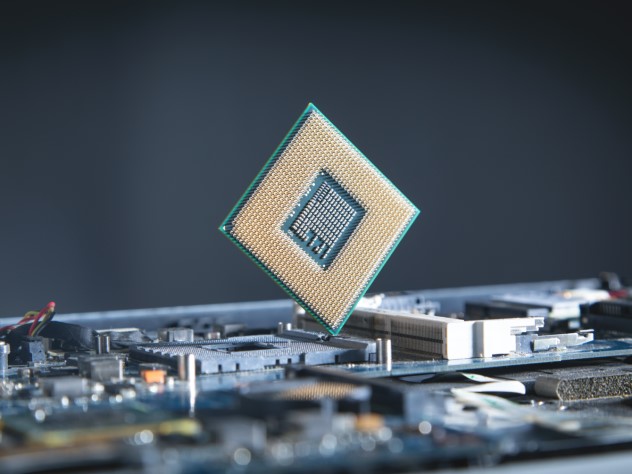

Sub-fab equipment transportation solutions

A complex network of equipment is required to operate a sub-fab, including chillers, heat exchangers, dry pumps, abatement systems, and more.

Sub-fab equipment must be kept operating at peak efficiency. Equipment maintenance and repairs must be organised and managed effectively. Failures need to be dealt with immediately and replacements sourced as quickly as possible. For any sub-fab, having a streamlined supply chain for critical equipment is essential.

Kuehne+Nagel offers you a robust and resilient logistics solution. We understand the complexities involved in cleanroom inventory management and sub-fab equipment installation. That’s why we provide end-to-end logistics solutions tailored to the unique needs of sub-fab facilities.

Optimize your sub-fab operations, reduce downtime, increase productivity, and avoid scrapped wafers. Our team specialises in semiconductor facility transportation logistics, maintenance logistics, and refurbishment logistics.

Contact us today to learn more about how we can provide you with complete support for the maintenance, repair, and replacement of your equipment.

Specialised semiconductor gases and chemicals logistics

Ultra-high purity gases are crucial at every step of the semiconductor supply chain, making proper gas delivery a critical component of the manufacturing process.

Semiconductor chemicals and gases must be delivered according to strict safety regulations and arrive in pristine condition, without micro-contamination. Without timely and reliable semiconductor chemical and gas transportation, the entire operation of a fab is put at risk.

Kuehne+Nagel can provide you with an iron-clad semiconductor gas supply chain.

As a logistics service provider, we understand the importance of timely and reliable delivery of critical chemicals that support semiconductor production processes such as etching, deposition, cleaning, and lithography.

Every aspect of semiconductor gas logistics is taken care of. We ensure special handling at every stage by highly specialised sub-contractors. Gases and chemicals are transported in temperature-controlled packaging with shock absorbers. Individual shipment monitoring is possible via GPS devices assigned to each shipment. Tracking modules can also measure light exposure and provide instant traceability on your shipment.

We use different modes and multimodal systems, such as Air Sea, to organise delivery against known expected delivery dates. For critical shipments, we use the fastest available routing 24/7.

Don't let uncertainty in delivery affect your production process. Partner with Kuehne+Nagel to ensure a well-functioning and high-quality logistics system for your gas delivery needs.